Pond Design and Construction

Ponds are built for a variety of reasons, but two basic rules remain the same. The pond must be sited on suitable soils and properly constructed to hold water, and there should be enough water available to fill the pond but not in great excess. Careful attention and expert advice on pond site selection and construction are essential. Once a pond is built, proper maintenance extends its useful life and beauty. In addition, most farm ponds depend on runoff from their watershed (land uphill from the pond) to fill and maintain the water level. Protecting the watershed ensures a quality supply of water to the pond.

For ponds built for recreational fishing, there is no advantage in deep ponds (over 12 feet to 14 feet deep) or to a deep area within the pond. Deep ponds are not more productive and tend to have more oxygen problems. Ponds should not have extensive shallow areas (less than 3 feet deep) unless aquatic plants are desired. Constructing ponds to drop off rather quickly to a depth of at least 2 1/2 feet helps prevent aquatic weed growth.

The Natural Resources Conservation Service (NRCS) publication "Ponds - Planning, Design, Construction" contains detailed information on design surveys, site selection, drainage area, pond layouts, soil analysis and spillway construction. It is recommended that you contact the NRCS for assistance in pond site selection and construction, to make sure the site, watershed, and soils are adequate. NRCS can ensure that you select the best location for your pond. Additional information on pond design and construction as well as other aspects of pond management in Arkansas is available in the publication "Farm Pond Management for Recreational Fishing".

|

Design and construction of pond farms

1. Type of ponds based on source of water supply

Springwater ponds, seepage water ponds, ponds fed by rainwater or run-off, ponds fed by water courses and tide-fed ponds; barrage ponds and diversion ponds - rosary or linked ponds and parallel ponds.

2. General layout of pond farms

Ponds (nursery, rearing, holding, brood, catching, transition or stunting ponds); water control structures (dikes, canals and sluices); and supporting facilities (roads, bridges, culverts, workshop, stores, farmhouses, etc.).

3. Planning of farm layout

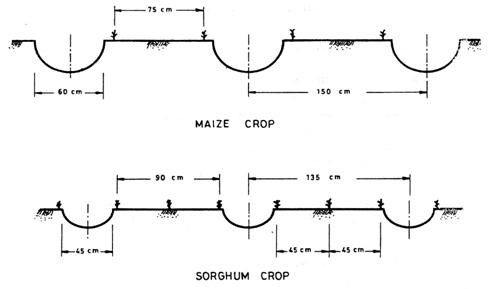

Preparation of farm layout plan, including water control system, based on physical features of the area, climatic conditions and requirements of farm management (production of fingerlings, table fish from either fry stage or fingerling stage); calculation of area required for nursery space; proportion of nursery ponds to production ponds, proportion of rearing pond area for different stages of rearing and area of holding ponds; determination of shape, size and depth of ponds; advantages of small and large ponds; optimum size of ponds for small-, medium- and large-scale culture operations; arrangement for adjustment of water level and salinity range of individual ponds in coastal farms.

4. Preparation of work plan

Quantification of input requirements; cash estimates; organizing supply of materials, labour and machinery; preparation of work schedule.

5. Site survey

Preparation of contour map; marking out the farm area; survey instruments required - levelling instrument with levelling staff, direct reading tachymeter with staff, theodalite, optical square, bevel protractor, tape and marking staff.

6. Site clearance

Clearance of vegetation from farm site by underbrushing, withering, felling and burning; removal of stumps; collection and later utilization of surface organic deposits as fertilizer or for facing embankments.

7. Design and construction of water control structures

7.1 Water control structures

Water gates and canals, levees or perimeter dikes and subsidiary dikes.

7.2 Basic principles for design

Calculation of water requirements; filling and drainage of pond farms; use of pumps, gravitation and/or tidal force for water supply and drainage.

7.3 Basic data required

For all farms - topography, soil properties, water supply, evapo-transpiration, seepage, magnitude of floods, rainfall, storms and cyclones; for coastal farms only - tidal range, river discharge, ground elevation and designed datum level.

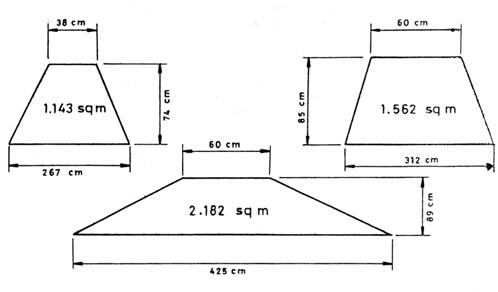

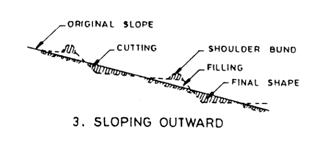

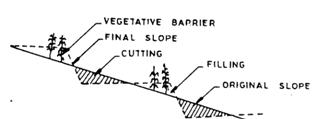

7.4 Design and construction of dikes

Determination of height, top width and based width of dikes; slope of dike in relation to soil type; construction of dike foundation and wall; measures for maintenance of foundation stability; excavation of core trench and core puddling in case of unsuitable soils; protection and stabilization of dikes - planting of vegetation, use of plastic sheets, bituminous emulsions, concrete, asbestos and timber reinforcements or wire mesh reinforcements; provision of roadways on dikes.

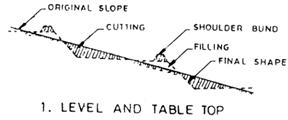

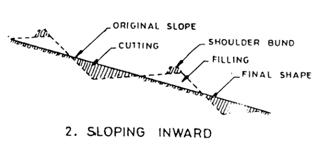

7.5 Levelling and sealing of pond bottom

Levelling of pond bottom, providing slope toward the outlet in case of flatland; sealing of the pond bottom to prevent seepage; materials used for sealing - clay lining, polyethylene or rubber lining, gley or biological plastic, bentonite clay and chemical sealants; construction of drainage ditches on pond bottom to facilitate drainage.

7.6 Design and construction of water gate structures

Main gate, secondary gates (division boxes) and tertiary gates; their dimensions in relation to volume of water intake and drainage; structure of main gate - tide-stream wing walls (in coastal farms), side walls, bed protection, sill and abutments; construction procedure; materials used.

Different types of inflow and outflow installations employed in individual ponds - Rivaldi valve, elbow joints, bottom water outflow, double sluice overflow, inlet pipes, sluices and monks; types of pipes used - earthenware, concrete, iron, polythene, PVC, etc.; installation of overflow pipe or construction of spillway; location and size of spillway.

Construction of diversion canal for diversion of excess or flood waters.

Different types of filters used with water control structures - wire screen, nylon mesh bag, sand or gravel, saran fibre, etc.

8. Pumps used in fish farms

Type of pump - piston, impeller, water-ram, Archimedean screw; lift, delivery, sludge and submersible pumps; freshwater and saltwater pumps; driving units - electric, diesel and petrol; their horsepower and delivery rates; suction and delivery pipes; foot valves; maintenance of pumps and simple repairs; possible use of wind power or other inexpensive sources of power for pumping.

9. Machinery used in farm construction

Earth-moving machinery - rooters, bulldozers, scrapers, excavators, draglines, clam-digger, suction dredgers, crawler (caterpillar) and rubber tractors, dumpers, tip trucks and sand pumps.

Earth-packing machinery - rubber rollers, vibrator rollers, road rollers, diesel rams and sheepsfoot roller.

Construction machinery - electric, diesel and petrol concrete mixers, vibrators, driving rigs and conveyor belts.

Power, working capacity, fuel consumption and running costs of different types of machinery; high capital cost; possibility of contract hire, period hire or cooperative ownership.

10. Economic aspects of pond farm construction Practicals

Survey of potential sites using land survey instruments; preparation of contour map; calculation of earth work; design of sluices; construction of typical pond farms; cost estimates for the construction of selected farms.

|